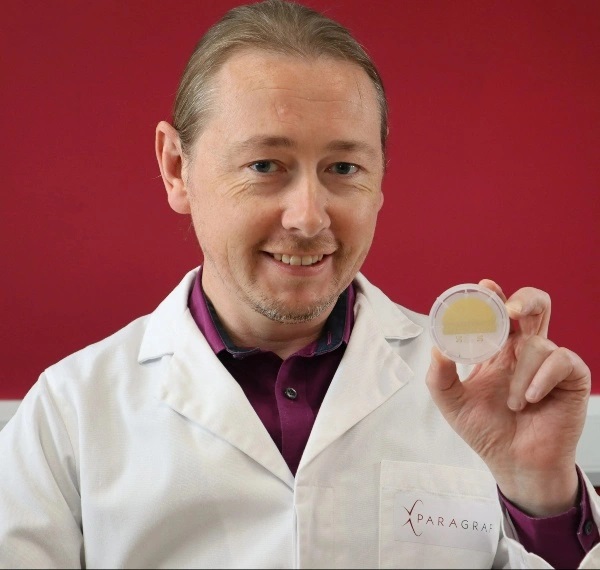

In this Q&A, Paragraf CEO Dr Simon Thomas describes the opportunities and challenges of scaling up a deeptech graphene pioneer.

What is the current size of Paragraf?

We have grown from 15 customers in 2021 to 35 as of October 2022. To this point, our customers have generally bought or used our products in small numbers for research and device qualification in their application purposes.

Investment remains our primary source of capital. We recently raised $60m in our Series B funding round.

We currently have 102 active employees, with five openings being advertised. The new facility we have recently secured will enable us to continue adding both personnel, equipment and production capacity. As a result, our recruitment is set to accelerate significantly and we expect to hit 200 active employees by the end of 2023.

Has the market evolved at the pace and scale that you initially envisaged?

As we are the first company to manufacture and sell graphene-based electronic devices, we are the engine that is currently driving the market’s evolution. The pace and scale of our growth has been as impressive as could be expected in the current environment, which in the UK can best be described as anti-manufacturing. This country simply is not yet equipped – in terms of infrastructure, talent or trade relationships – to nurture the sort of deep-tech manufacturing that we do.

While much has changed in the business environment since the company began – primarily as a result of the cultural shifts created by the pandemic, but also with changes in the ecosystem being caused by semiconductor supply chain shortages and geopolitical tensions – our efforts to realise the potential for graphene-based electronic devices have continued without significant delay.

Outside of Paragraf’s operations, the seemingly endless uses envisioned for graphene has resulted in a rush to produce a wide array of graphene-based products. That has led to many strange uses for the material that were never on our radar. One aspect of the graphene market we may have failed to appreciate is the need to demonstrate that we aren’t selling snake oil or simply using “graphene” as a buzzword. Our technology is genuine – and genuinely game-changing – but the scepticism with which that reality is often met is a larger obstacle than it would have been had the graphene “Gold Rush” not featured so many questionable applications.

How has Paragraf’s growth to date been assisted by the Cambridge scaleup ecosystem?

Paragraf is a spin-off of the University of Cambridge’s Centre for Material Sciences and Metallurgy, so the company is a product of the local ecosystem. That association has provided links to sources of talent, capital, association, technical services and market insight.

Theoretically, the university and the well-established tech industry in the region have made Cambridge an attractive destination for skilled people wishing to work in the industry. Likewise, it is appealing to venture capitalists seeking strong investment opportunities.

The ecosystem is not an entirely welcoming environment for a business like ours, however. The prestige of a Cambridge address has proven irresistible to large technology, pharmaceutical and scientific companies, which has driven up salaries and property costs to a degree that smaller companies are hard-pressed to compete.

To date, what have been the most challenging barriers to growth?

Hiring the appropriate talent for our technology has been a challenge, both because of what we do and because of the number of people we need. Epitaxy and CVD are special skills, and there is massive competition from established industries for those with experience in these areas. Our efforts to bring something new to the market are attractive to some scientists with those skills; but a scaleup environment is only particularly interesting to a select group. Similarly, building a business from scratch has meant that we have needed to attract talent in all facets of the business. We also needed HR and facilities functions in order to begin staffing and supporting the company’s employees. Those teams have been building out our operations, facilities, sales and marketing teams at a tremendous pace.

The type of work we do also requires highly specialised manufacturing equipment, which is expensive and not readily available. The machines themselves use technologies and components from multiple sources, and both the equipment and components must often be imported – which involves a host of supply chain issues and dealing with customs and trade agreements that complicate the purchase process.

Brexit has presented to us the same challenges that many other businesses in the UK have experienced, in that it has complicated matters with our closest trade partners in the EU and has taken us out of trade agreements with countries outside the EU. Recruitment is made more challenging because we no longer have ready access to EU nationals who can fill vacant roles. Further, buying and selling – as well as business travel – between the UK and the continent has been made more difficult in the absence of the customs union.

That said, the reality of Brexit does offer the UK an opportunity to bolster the prospects for businesses like us. The purpose of ‘taking back control’ of our immigration and industrial policies should mean that, rather than having been dependent on business and talent solely from the EU, we can now open ourselves up to the rest of the world. However, in order to do that, we need the government to negotiate trade agreements that will provide us the opportunity to take advantage of work visas from around the world.

Paragraf successfully weathered the storm of Covid shutdowns in the UK by following government guidelines and implementing safe workplace practices in order to enable our manufacturing and research to continue on-site. Hiring staff also progressed; we saw 18 new starters in 2020, 22 in 2021, with 35 in the first three quarters of 2022.

Similarly, we have managed around the semiconductor supply-chain issues of the last couple of years to bring in the highly specialised equipment required to expand our production lines and meet product delivery objectives. As would be expected with the extended lead times and continued squeeze on supply, we have secured further equipment in order to develop our second manufacturing site and grow our output capacity according to plan over the next year.

What is the scale of the market opportunity and what are your growth ambitions?

There truly is no ceiling on the opportunity or our ambitions. Our aim is to design, develop and manufacture electronic devices using graphene as the primary conductive element. Electronic devices are ubiquitous in the modern world and only stand to grow more so. Graphene, when it is properly manufactured, has a host of advantages over conventional materials (e.g silicon, gallium arsenide) which means that it can supplement or even replace those materials in existing technologies and expand what’s possible with future devices.

Paragraf raised $60m in its Series B round earlier this year, with some of the funds through the Future Fund: Breakthrough: what was your thinking behind the mix of new investors?

Our Series B round includes both ambitious UK investors and investment companies backed by the UK and US governments. Raising funds in the way we have done for Series B has extended our reach beyond solely the UK and demonstrated that the US and UK governments are supportive of our developments.

In an interview with The Times this year, you were quoted as saying: “If we hadn’t had Covid, would we be opening up elsewhere? The world would have been more accessible to us when we were looking for another site. I think the answer is yes.” What support needs to be in place to ensure that Paragraf can scale up further and achieve its full global potential as a UK-based company?

There are a couple of key things the government can do to make the UK a more hospitable location for businesses like ours. The priority we would like to see them adopt is to open up access to talent and equipment from abroad. Our operations are complex and the resources we need to accomplish our goals are not entirely available locally. Again, this is an opportunity for the government to make these things available to Paragraf and similar businesses by opening up to the entire globe, providing visas to skilled immigrants wherever we find them, entering into trade agreements that allow us to buy and sell abroad with fewer impediments and generally making it easier for people and goods to get into and out of the country.

The other priority we have asked the government to adopt is infrastructure development. The manufacture of semiconductor devices requires far greater energy than is generally available on the grid. The UK is able to make use of a variety of energy sources but for industrial purposes that energy needs to be concentrated in areas where it can be available for non-standard uses.

The US already has a plug-and-play infrastructure that would allow us to open up a manufacturing site instantly with all necessary utilities and a supportive industrial ecosystem. Some other countries have similar facilities. SelectUSA has already provided us with information on specific locations that are rich in both the relevant skilled personnel and other businesses within our ecosystem. Similarly, they had information available about various local incentive programs in place from which we could benefit if we were to relocate there. To date, we have received no support on that level from the UK government.

We are a British company. We wish to remain a British company. However, we also need to be a global company. We need investment from outside the UK and we certainly need customers outside the UK. If we can’t accomplish those things by housing our operations here, we simply won’t be able to continue to be British, except by origin.

What do you want to see in the Government’s national semiconductor strategy?

First and foremost, we want to see the government have a semiconductor strategy. Paragraf and companies like ours will be able to adjust to whatever reality emerges from the government’s consideration of the issue. Even if they decide that there is no interest in hosting the semiconductor manufacturing industry here, we would be able to choose from a number of potential destinations. That clearly is not our preference, but the worst possible outcome would be no definitive outcome. Keeping these businesses in limbo, wondering whether or not to pursue a future here won’t serve anyone’s interest.

That said, we certainly want to see the government embrace the idea of enabling the semiconductor industry to grow here.

Diary of a graphene scaleup

Since Paragraf was founded in 2017, the company and its technology have passed several major milestones.

2019

- First manufacturing facility produces graphene chips

- Completes $22.5m Series A funding round

- First sensors are shipped to a customer

2020

- Announces partnerships with CERN, Rolls Royce and TT Electronics, and NPL

2021

- Launches cryogenic sensor and capabilities demonstrated by Oxford Instruments and the High Field Magnetic Laboratory (HFML – part of the European Magnetic Field Laboratory [EMFL])

- Delivers biosensor proof-of-concept

2022

-

- Closes $60m Series B funding round

- Ships new ‘small’ magnetic sensors and Multi-Sensor Test (MiST) kits to customers

- Awarded £550,000 Biomedical Catalyst grant from Innovate UK in collaboration with the Universities of Liverpool, Manchester and Newcastle, Newcastle upon Tyne Hospitals NHS Foundation Trust and Manchester University NHS Foundation Trust (MFT) to develop a proof-of-concept combined PCT (procalcitonin) and CRP (C-reactive protein) test on a single panel. The aim is to develop a new generation of graphene-based, in-vitro diagnostic products that will at least match the performance of the most advanced hospital laboratory, but at the point of care.

- Recognised in the TechNation Future Fifty programme

- 100 active employees by September

- Begins fitting out a second manufacturing facility in October

There truly is no ceiling on the opportunity or our ambitions. Our aim is to design, develop and manufacture electronic devices using graphene as the primary conductive element.

Dr Simon Thomas, CEO